Asphalt Maintenance In Four Easy Steps

Step 1: Clean The Surface

First, clean out asphalt cracks with a screwdriver or a machine designed to do the job. Any fuel or grease stains need to be cleaned off with a specially formulated degreaser. Finally, the entire surface needs to be cleared of debris, using what works best for you and your budget. Whether you use a broom, a blower, or a pressure washer, make sure your asphalt is clean and dry.

Step 2: Repair Any Damaged Areas

Any cracks or potholes need to be dealt with using quality asphalt crack filler and the proper crack-sealing equipment. Small and large asphalt cracks should be repaired before they become even larger cracks. Sooner or later the larger cracks turn into potholes and depressions, resulting in costly repairs or, in extreme cases, complete replacement ($$$).

- Cold Crack Filler: This is the perfect fix for cracks a half inch wide and smaller. Be sure to tightly pack sand in the crack so that it's no deeper than a half inch, and apply the crack filler as directed.

- Hot Pour Rubberized Crack Filler: Intended for repairing cracks larger than a half inch, this method requires planning and proper temperatures. You will need a way to heat the hot pour and a way to apply it. This can be done with a melter oven and a crack pour pot, or you could use a 2-in-1 machine like the RY10.

- Cold Asphalt Patch: This is your pothole miracle fill. Cold asphalt patch is completely pliable out of the pail and sets perfectly. It's suitable for using at any time of year. If you're using cold asphalt patch, you want to tightly pack sand to bring it up to one inch in depth before applying. Also, to allow for settling, slightly overfill the hole. A vibrating plate is useful for tamping sand and asphalt repairs.

Step 3: Sealcoat Your Asphalt Surface

We recommend that you sealcoat your asphalt surface every two years so that you prevent further decay and oxidization. Delaying the treatment of your asphalt surface will invariably end up costing you a lot more money (thousands of dollars) down the road. Sealcoating is never more important than after asphalt crack repair! Once the repairs have cured, driveway sealing is your final step to ensure the repair is sealed and protected.

Step 4: Block Access

Block access is really important to stop foot and vehicle traffic from messing up your work when you're away. Use caution tape, and/or pylons, to protect your asphalt area during curing and drying.

Asphalt Ingredients

So what is asphalt and its ingredients? There are two basic ingredients in asphalt. The first are aggregates: a mix of crushed stone, gravel, and sand. Aggregates make up about 95% of hot mix asphalt pavement.

So what is asphalt and its ingredients? There are two basic ingredients in asphalt. The first are aggregates: a mix of crushed stone, gravel, and sand. Aggregates make up about 95% of hot mix asphalt pavement.

The other 5% is bitumen. Bitumen, composed of polycyclic hydrocarbons (a petroleum byproduct), is the black or dark viscous material that holds the aggregates together.

The rock and sand give asphalt the strength required for high traffic zones and years of heavy weight loads. Tar and bitumen, on the other hand, are the liquid components which give asphalt its flexibility. Asphalt is designed to flex as the ground moves and yet remain solid enough for heavy cars and trucks to drive on it.

The elemental components of asphalt, for those interested in a deeper understanding of its ingredients, include carbon, hydrogen, sulfur, oxygen, nitrogen, and trace amounts of iron, nickel, and vanadium.

Asphalt Types

There are several different types of asphalt, and they are categorized by the process used to bind aggregate with the bitumen.

- Hot mix asphalt concrete is produced under high heat and is the most durable of the asphalt types. It is generally used in high-traffic applications such as on highways and airport runways.

- Warm mix asphalt concrete does not require high temperatures for manufacturing because of the addition of emulsions, waxes, and zeolites. While it is safer for the environment and workers and uses less fossil fuels in its production, warm mix asphalt concrete does not offer the same level of durability as hot mix asphalt concrete. Thus, it is primarily used for low-traffic areas or for patching.

- Mastic asphalt has less bitumen content than hot mix asphalt concrete and is commonly used for roads, footpaths, play courts, and roofing.

Regardless of its type, all asphalt needs some maintenance to provide extra protection and durability.

Asphalt Durability

If you've ever been jarred by a crack in an asphalt road, you know that the material doesn't last forever. The performance of asphalt can vary widely depending on a number of variables that include the presence of moisture, temperature fluctuations, volume of traffic, and exposure to certain chemicals. Even varying asphalt ingredients can determine its durability.

Because asphalt can hold the weight of vehicles, it is the material of choice for roads, parking lots, and driveways. It can be applied rapidly and can be patched easily by pressing it directly into cracks and potholes.

Over time the elements (sun, heat, u/v rays, cold, rain and snow) cause the asphalt to dry out and lose its flexible properties (the tar and bitumen). The sun basically cooks (dries out) the liquids out of the asphalt surface, leaving a fragile gray surface that is bound to crack and deteriorate very quickly. Other factors that may cause asphalt to erode and decay include heavy traffic, as well as the expansion and contraction process.

Asphalt goes from a very deep black color when it's first applied to a grayish color over time. This graying process is caused by "oxidization."

When an asphalt surface appears gray and shows signs of drying out, then it's time for the asphalt surface to be sealcoated with a commercial grade asphalt sealer product and the proper sealcoating equipment to rejuvenate and protect the asphalt surface from the elements.

Learn More: Enroll In Our Free Course

Pavement Asset Management Course

Register Now

This free asphalt driveways course is everything a property owner needs to know about asphalt maintenance and repair.

What Is The Most Effective Maintenance Strategy For Asphalt?

Homeowners, it's important to understand the ingredients in asphalt, because it does need to be maintained on a regular schedule. An asphalt driveway can remain in good condition for decades if it is properly cared for.

Knowing what can negatively affect asphalt ingredients is also important. Since oil, grease, gas, salt, and transmission fluid can break down the quality of asphalt and ultimately result in cracking and crumbling, these substances should be cleaned up quickly if spilled on asphalt.

Crack Filling

As part of preventative maintenance, asphalt should be inspected for cracks. Even small fissures that go un-repaired or unfilled can cause the ingredients in asphalt to deteriorate. With all types of asphalt, a certain amount of cracking is inevitable. The secret is to fill the cracks before they expand and turn into potholes or larger areas of crumbling pavement. There are two types of crack filler that can be used on any asphalt or concrete surface.

- Cold liquid pour asphalt crack fill is highly effective in sealing cracks up to a half inch in width. The product is easy to use and keeps cracks on all types of asphalt sealed for several years.

- Hot pour crack fill is commercial-grade rubberized asphalt crack sealer that works on cracks up to one inch in width. It can be safely heated in a kettle or crack fill applicator melter and poured into cracks to seal out water, ice, and debris. Hot pour crack fill will keep cracks sealed for up to four years.

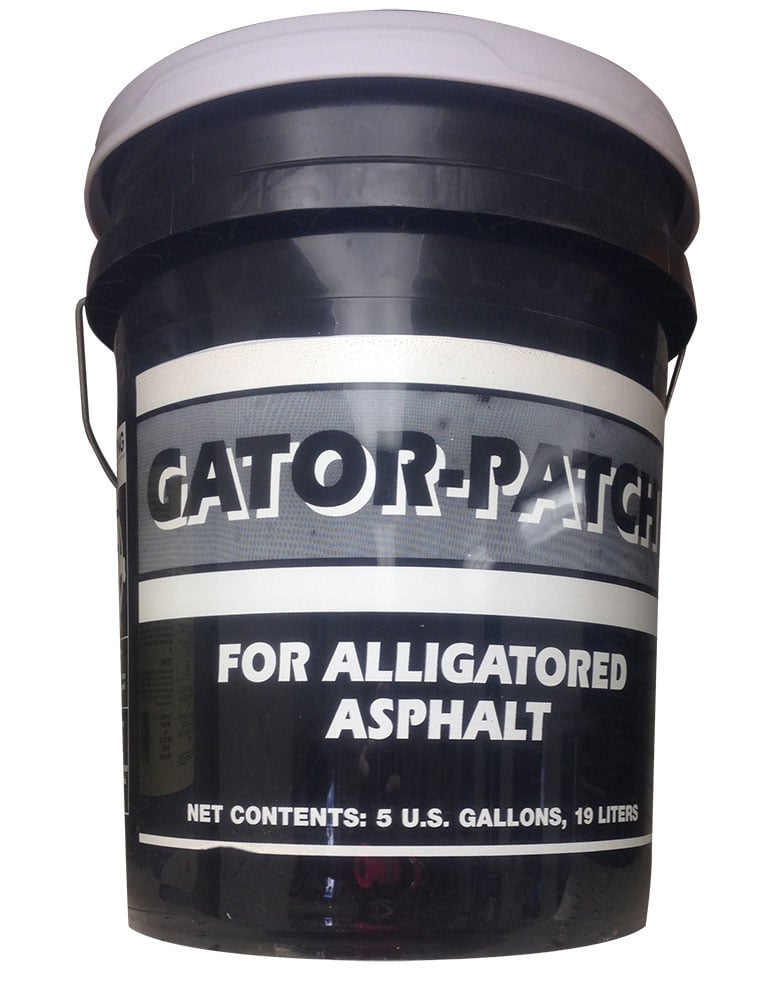

- Gator Patch is a crack filler specifically made to patch alligator cracks. If you have areas of asphalt with many intertwined cracks that look like the back of an alligator, use Gator Patch to repair these cracks and seal water out to prevent further damage.

Sealcoating

All asphalt types require proper maintenance and proactive repair to retain their appearance and overall condition. The use of a sealcoat is essential to the proper maintenance of any asphalt surface. While there are a number of sealing products on the market, we only recommend the use of asphalt emulsion sealer because of its ability to create an effective buffer against traffic, water, oil, salt, and other staining agents. Asphalt emulsion sealers also protect the bitumen from oxidizing, becoming brittle, and cracking.

Asphalt emulsion sealers are easy to apply with either a spray system or a squeegee and dry quickly in three to four hours. Whether you have a driveway or a parking lot for your business, sealcoating asphalt should be a priority.

When asphalt ingredients aren't properly protected with a coat of sealer, they will inevitably crack. Leaving even small cracks and fissures exposed and un-repaired will definitely lead to more serious damage such as potholes, crumbling asphalt, and foundation damage. This ultimately results in the need for costly asphalt replacement.

Cleaning Your Asphalt Surface

It's important to clean asphalt to maintain its condition and appearance. This includes sweeping away debris, removing stains, and scouring the surface on a frequent basis. Clean asphalt is less prone to cracking and deterioration.

Cleaning a parking lot using a backpack blower

The Process

To keep a driveway clean, scrub the asphalt's surface with a mixture of detergent and water, and hose off thoroughly. For stains from oil, gas, or transmission fluid, use a commercial driveway cleaner designed for cleaning asphalt. Specifically, look for an eco-friendly, biodegradable oil stain removal product that does not contain ammonia. Asphalt Kingdom has an effective oil stain removal formula that works on any surface stain and is not an ozone-depleting solvent.

The Extras

As part of a maintenance program to clean asphalt, it's essential to repair cracks. Cracks can be sealed quickly with either Hot Pour Crack Fill or Cold Liquid Pour Asphalt Crack Filler. This commercial-grade product can be poured directly into asphalt cracks and smoothed off. Filled cracks dry in less than an hour, leaving you with crack-free, clean asphalt.

Another important component to keeping a driveway clean of discoloration and cracks is by sealing the asphalt. Not only does using an asphalt emulsion sealer protect asphalt from the elements, it also helps maintain the appearance of clean asphalt by repelling water that can seep into small fissures and preventing stains from occurring. With regular driveway sweeping, cleaning, and sealing, asphalt can hold up to the elements for many years.

Like driveway cleaner, it's important to look for a sealer that is both commercial-grade and environmentally friendly. You can order asphalt emulsion sealer directly from the experts at Asphalt Kingdom.

Looking for a safe asphalt cleaner for your company? We have the solution that is certainly a much more effective and environmentally-friendly cleaner than paint thinner or petroleum-based products. It's called Asphalt Kingdom Oil Eater and you can find it at our Stain Removal Store.

Asphalt Kingdom's Asphalt Degreaser penetrates oil and surface stains on asphalt like no other product on the market. The Degreaser safely cleans stains while leaving no surface residue or streaks. It's a must-have product for cleaning large expanses of pavement and keeping any driveway clean. Asphalt Kingdom can deliver Asphalt Degreaser directly to your door in both 5 gallon pails and 45 gallon drums.

Preventative Measures

Once the asphalt surface starts to lose its flexibility, it will begin to crack. Small asphalt cracks should be sealed before they become large cracks. Eventually, the large cracks turn into potholes and depressions resulting in costly repair or, in extreme cases, complete replacement ($$$).

The present price of oil has dramatically impacted the price for asphalt on a per ton basis. The cost of asphalt paving or replacement is high, which has increased the demand for more asphalt sealcoating companies and in-house maintenance programs. Commercial property owners and driveway owners are starting to understand that it is much more economical to maintain their own asphalt on an ongoing basis.

How Can You Benefit?

Commercial property owners and parking lot managers save thousands of dollars maintaining their own parking areas. Learn how you can save thousands on hefty asphalt replacement costs by developing an in-house maintenance program. All of the steps to do this can be emailed to you with our free Pavement Asset Management Course.

Residential home owners can learn how to seal asphalt to maintain their driveway and beautify their property with a minimal cost investment. Get all the info sent to your inbox with our free Homeowners Course for asphalt maintenance.

You can learn more about maintaining your asphalt and the steps that need to be taken to maintain your asphalt surface with our FREE Four Day Asphalt Maintenance Email Course.

Give us a call Toll Free 1-866-399-5562 or email us your question: you'll get answers you can count on.

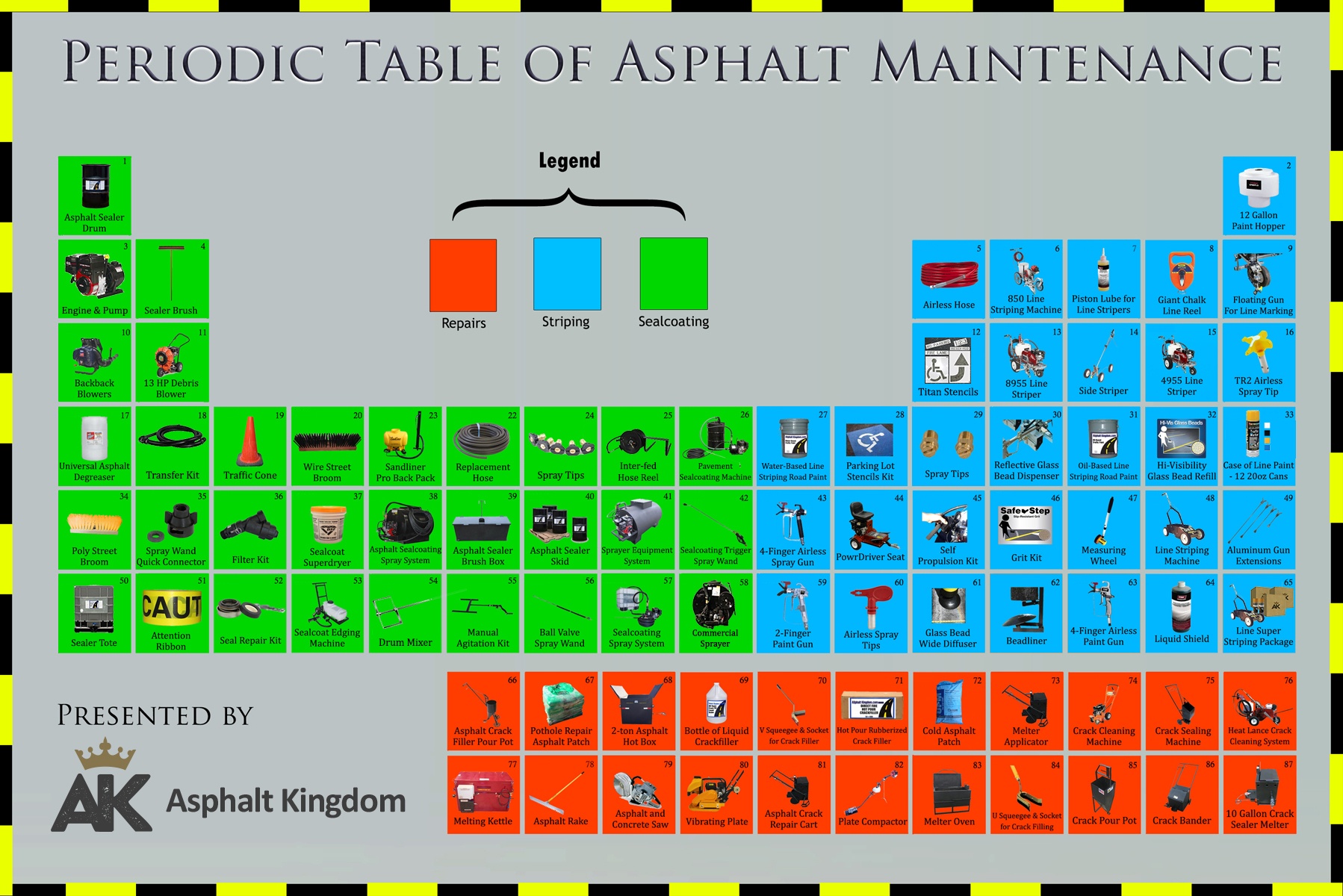

The Periodic Table of Asphalt Maintenance

We've compiled this Periodic Table for your viewing pleasure:

Learn More: Enroll In Our Free Course

Pavement Asset Management Course

Register Now

This free asphalt driveways course is everything a property owner needs to know about asphalt maintenance and repair.

Seasonal Considerations Associated with Asphalt Maintenance

The dramatic changes in weather associated with different seasons can significantly impact the condition of your asphalt. In order to properly maintain your asphalt surface, you will need to understand the important role seasonal weather plays in this process. Below are a few tips to help you adjust your maintenance efforts by season.

Spring/Summer: Your 5 Point Checklist

Before the sticky-tar days of summer settle in, there are 5 items to check off on your to-do list. Once the heat hits, you certainly will not want to be out there on the hot blacktop trying to get your asphalt repair done. Here is your 5 point pre-summer checklist, in order of doing, for your blacktop maintenance.

- Edging

No matter what you have bordering your blacktop, this is the first place that damage creeps in. If you have lawn or flower beds, grass and weeds find the strength to start making inroads and cracking the edges. Concrete curbs and gravel borders still have seams where those grass and weed plants find their way in. Start by edging any adjoining lawn, and clearing a one- to two-inch border. Weed your flower beds, and make sure perennial plants aren't getting too close. You can trim edges with equipment such as Hedgehog Asphalt Crack Cleaner & Lawn Edger. With curbs and gravel, you can do a quick, permanent kill by pouring vinegar to kill the plants. - Spring Cleaning

It may not sound like asphalt repair, but it is! For superior blacktop maintenance, always clean up any fuel and oil spills as soon as possible. Those spills will eat away your blacktop at an alarming rate. To clean them, use a degreaser cleaner engineered for asphalt and a stiff brush or broom. Using a pressure washer is a bad idea as it drives the stain deep into pores of the blacktop. When you've finished removing all the stains, wash and/or sweep the entire surface to complete the cleaning portion of your blacktop maintenance. - Pothole Filling

Repairing potholes is clearly a necessary part of asphalt repair, and it's a surprisingly easy job you can do yourself. Begin by clearing all the loose pieces around the edge using a hammer and chisel, or an old screwdriver, and square up the edges. Top up the hole to a 2-inch depth with coarse gravel and sand, and tamp it down firmly with a 4 by 4. Finish the asphalt repair by pouring in cold patch and tamping down.

Tamping Down Tip: Don't have a compactor? Use a sheet of greased plywood, greasy side down, and drive over it for compaction. - Crack Repairing

Crack repair is hands down the most neglected part of asphalt maintenance. It's also the one that causes the most damage and most often results in needing a complete asphalt replacement. You can do your own blacktop maintenance of repairing cracks that are a half-inch wide or less.

Clean the crack of debris, top up to a half inch depth with gravel sand mix (just like for #3. Pothole Filling). Pour in liquid crack filler and squeegee flat. Asphalt repair of larger cracks can be filled with the cold patch for potholes, or better yet, hire a professional to use hot pour rubberized crack filler. Large property managers would do well to invest in this type of crack filling equipment to save money by doing the maintenance for themselves. - Sealcoating

Sealcoating regularly for blacktop maintenance is your best insurance against future costly repairs. Sealant works by replacing the surface lost to oxidization from sun, air, and rain. Think of it being the same as a combination sun screen and skin moisturizer: sealcoating protects and rejuvenates. How do you know when it's time to do this type of asphalt repair? Try the water test: if you pour water on the driveway or parking lot and it no longer beads on the surface, it's time.

Be sure to buy an airport-grade quality sealcoating product for long-lasting results. This too is an easy blacktop maintenance job you can do yourself. Simply apply to a clean surface, as thinly as possible, with a brush or squeegee. Allow to cure (dry), and apply a second thin coat if necessary.

Tip: One thick coat will not cure properly and will ruin all your hard work.

Hot humid days are horribly unpleasant for getting your blacktop maintenance chores done. Plus, when your blacktop is hot enough to fry an egg, it's going to make it difficult to work with cleaners and sealers, since they will dry too fast. Get out there and work the 5 steps; edging, cleaning, asphalt repair of potholes and cracks, and finish with sealcoating. Now you're an asphalt maintenance expert!

Fall: Asphalt Maintenance

The early October snowstorm is a reminder that weather is an integral part of professional-looking asphalt. Suddenly, we have to ask if there is still time to do the driveway sealing and to tackle crack repair. This is especially important as we know the freeze and thaw cycles will make all driveway cracks larger!

- Sealcoating Driveway Maintenance: Sealcoating is a crucial part of protecting your asphalt. The right temperature is essential for the proper curing of the sealer; you must have a surface temperature of 50°F or 10°C. What is too often forgotten is that a blacktop driveway soaks up the sun and is warmer than the air. By noon it can be as much as 15°F hotter! Use a thermometer and see if you can still get your sealcoating asphalt maintenance done before winter really sets in!

- Crack Repair Driveway Maintenance: Cracks allow water to pool, and as the freeze and thaw cycles expand and contract that water, the cracks keep getting bigger. That's why it is such an important part of asphalt maintenance! Fortunately, crack fill is not temperature dependent, as hot pour crack filler does not contain water. All you need to ensure is that the crack is completely dry before filling, which is easily done with the torch on the RY10.

Don't let an early snowstorm stop you from asphalt maintenance! If you haven't sealed your pavement yet, take a temperature reading and see if there's still time. As far as filling cracks goes, as long as you dry out the area thoroughly, that's driveway maintenance you can tackle all year long!

Winter: Damage to Asphalt Surfaces

There are three main areas affected by a hard, heavy-snowfall winter: First, the constant scraping of snow plows can mean that parking lot lines have all but disappeared. This decreases a parking lot's efficiency as fewer cars can park and people don't know which direction to take in parking lanes. In some cases, if state-regulated handicapped spots are scraped off, parking lot owners could even face fines for non-compliance.

There are three main areas affected by a hard, heavy-snowfall winter: First, the constant scraping of snow plows can mean that parking lot lines have all but disappeared. This decreases a parking lot's efficiency as fewer cars can park and people don't know which direction to take in parking lanes. In some cases, if state-regulated handicapped spots are scraped off, parking lot owners could even face fines for non-compliance.

The second area to watch is cracks: cracks that weren't properly cleaned, filled, and sealed before winter may have let moisture into the foundation of your asphalt, and could have compromised the whole surface, necessitating costly repairs. If you see a depression forming around a crack, it is likely that you have foundational damage.

Thirdly, untreated cracks and areas of pooling water that freeze and expand may have resulted in potholes showing up in your pavement. Potholes are at best a risk to your pavement and at worst a dangerous hazard to drivers and pedestrians alike.

The easiest and fastest way to address the problems is to hire an experienced asphalt contractor to come out and look at your parking area. However, after a winter such as this one, it could be difficult to book one any time soon. If you prefer to do it yourself, there are several helpful guides available online to teach you what you need to do and what equipment and supplies you need to do it with.

Homeowners: Protect and Increase Your Property Value with High-Impact Home Improvement DIY

Let's face it: property values are diving and whether you are looking to sell your home or just to stand out on your street, you need an edge in today's market.

One of the fastest and least expensive ways to increase your home's 'curb appeal' is to restore and maintain your asphalt driveways and walkways.

For a fraction of what you'd pay to have your driveway professionally resurfaced, you can do it yourself. Think driveway home improvement DIY is too hard?

Relax: our easy online four-part asphalt maintenance course tells you exactly what you need to know to clean, prepare, crack-fill and reseal your driveway. You'll get professional-looking results in no time!

Asphalt requires regular care and maintenance to be kept looking like new and there's nothing worse than a cracked and faded driveway to drag down the value of your home and property. Whether you are wanting to maintain your asphalt surface yourself or wanting to start your own money making asphalt sealing business with the skills you learn doing home improvement diy, we definitely have all the solutions that are right for you.

Our customers love our high-quality products and some have even started their own Asphalt Sealcoating Business using our proven Asphalt Business-in-a-Box. This all-inclusive, no-franchise-fee system contains everything you need to add instant dollars to your income in your spare time.

"We ordered an AK Spray System and some Crack Filling Equipment along with their sealer and crack filler and must say that their service and equipment are as good as they say they are. We have maintained our restaurant parking lots and saved a lot of money."

-Willie Sease, Maintenance Manager - Popeye Chicken Restaurants

Send Us Your Asphalt Information for a FREE Personal Consultation regarding anything to do with your asphalt surface or the asphalt surface you're looking to protect. We will provide you with free expert guidance and support to be sure that all your asphalt surfaces are maintained.

If you're looking for another fast-and-easy home improvement DIY idea, why not consider landscaping your front porch? Our friends at Front Porch Ideas have dozens of ideas and gorgeous photographs that are sure to inspire your home improvement ideas.

Learn More: Enroll In Our Free Course

Pavement Asset Management Course

Register Now

This free asphalt driveways course is everything a property owner needs to know about asphalt maintenance and repair.

Parking Lot Maintenance: A Routine to Help You Save Big Bucks

Routine parking lot maintenance is essential. If you're in the habit of waiting for a pothole to swallow your car in order to pay attention to your asphalt, you're about to discover how routine pavement checks, in the spring and the fall, will set you free from tedious and costly asphalt repair.

Let's face it: the first place customers and clients see when they arrive at your property is the pavement! If the parking lines are scraped off or there are cracks wide enough to snag shoes, you aren't making the impression you want to make. Plan to check your parking lot on the first day of spring and the first day of fall, and get into the habit of taking care of this investment as well as you take care of the inside of buildings on your property.

There are 4 main things you should check for when doing your asphalt maintenance routine:

1. Fixing Potholes and Cracks First

Here is where you will save the most money if you spot asphalt cracks early. The savings here is huge, because neglected cracks allow water to get underneath, and it will destroy the foundation of the parking lot. That's a sure way to end up with parking lot replacement! By crack filling early, as part of your parking lot maintenance, you will greatly extend the life of your asphalt. Watch for grass or weeds growing up through the pavement and thin spidery lines known as alligator cracking.

There are 3 steps to fix cracks:

- Clean the damaged area (all debris, weeds, and loose asphalt).

- Make sure your crack is 1" deep. If it's deeper, top up with coarse gravel to 1" depth.

- Fill the damaged areas as follows:

• Small cracks (1/2" or narrower) with cold crack filler

• Cracks from 1/2" - 1" with hot pour rubberized filler

• Potholes and cracks larger than 1" with cold asphalt patch

We also have a Gator Patch to fill in alligator cracks and shallow potholes.

2. Cleaning Stains the Best Way Possible

You must have noticed when looking for cracks that many of these occur where there is a fuel stain. This is because gas, oil, and other spills eat through the asphalt. A lot of crack repair can be avoided by taking the time to clean these stains as part of your regular parking lot maintenance.

It's important to use a degreaser cleaner for asphalt, as many cleaners are just as harmful to asphalt as the fuel stains. Another important consideration is whether to use a green and environmentally-friendly formula. If you use an eco-friendly product, you won't damage any flowers or grass that edge the lot, and you don't have to worry about storing or using a toxic chemical.

We have an environmentally friendly asphalt degreaser that's perfect for parking lots.

3. Maintaining Asphalt By Sealcoating

Do you need to sealcoat? This is simple to check: pour water on the surface and see if it beads up and rolls off. If it does, it's in great shape. If not, it's time to apply a sealcoat. Usually, every 2 years is a good schedule, but doing it too often can actually cause the surface to start peeling. This is also a good way to avoid or protect crack repair, as sealcoating keeps the surface from drying out and becoming prone to cracking.

To sealcoat you need to have a clean parking lot, with all cracks repaired and any grease stains cleaned up.

Make sure you have no rain for the day and that temperatures are above 60°. You can either use a broom or squeegee to manually apply the asphalt sealer, or you can use a sealcoat machine. Learn more about sealcoating your parking lot or sign up for our free parking lot maintenance course.

4. Line Striping to Maintain Asphalt Safety

One of the most important aspects of a parking lot is its parking lines. If there are faded lines or you've sealcoated your lot, it's necessary to refresh your lines with a new paint job.

One of the most important aspects of a parking lot is its parking lines. If there are faded lines or you've sealcoated your lot, it's necessary to refresh your lines with a new paint job.

This is especially important during the holidays when you are likely to have more traffic through your parking lot. Also, if there's snow, ice or de-icing products covering your parking lines, they'll be much harder to see; make it as easy as possible for your customers to see where to park by using fresh coats of paint.

There are 4 steps to perfect parking lot striping:

- Clean the surface (debris, dust, loose paint, etc.)

- Block the area to traffic. Consider painting when your business is closed, or block off a section at a time.

- Paint with quality traffic paint using a line striper suited to your parking lot.

- Allow your paint to dry before letting traffic through. Look at your paint specs to determine the drying time.

Learn more with our free Line Striping course here.

Don't forget the loading bay! Deliveries are far easier and smoother if everyone can see exactly where the lines are. Consider adding hi-visibility beads to your fresh paint job, for the ultimate in clear parking lot lines.

Parking Lot Maintenance Tips

Maintaining asphalt is not difficult, and by keeping it as a part of your routine as a property manager you'll save a lot of money. A dollar spent in upkeep will save you $6 to $14 in repair. Not only that, but customers and clients will have a great first impression of your property by seeing the care you take in parking lot maintenance!

- Smart planning saves work: One of the easiest ways to make parking area maintenance a snap is to think ahead. Consider what having a garbage can available can do to cut down on litter. Rest stops and fast food joints know this well, and they keep trash cans plentiful and in the right locations. Close to the entryway is always the simplest way for people to find it, but if your lot is large, one is probably not enough. Don't forget to make sure they are secured for windy days, and empty them frequently.

- Work smart, not hard: Keeping the lot clean and tidy is more than painstaking with a broom, it's downright hard! A gas blower can make short work of leaves, dirt, grass clippings, and other debris. Parking area maintenance shouldn't be a job you avoid, but a simple task that needs doing. With a blower to push everything into a corner, now you have all the debris in one place to dispose of.

Poorly-maintained parking lots are an eye-sore, dangerous, and reflect badly on your place of business. By cleaning up fuel spills you prevent slip-hazards and protect your asphalt from damage. Putting a little thought into garbage cans and their placement will cut back on the litter in your lot. Having the right tools to clear debris means the job gets done faster, easier, and you won't put it off! Parking area maintenance keeps your place looking great and makes it safer too!

Shop Related Products

AK130 Residential Sealcoating Machine

RY10 PRO Asphalt Crack Fill Machine

Gator Patch

Have questions? Looking for expert asphalt advice?

Call us toll free at 1-866-399-5562 or send us a message: you'll get the facts, information and expert advice you can count on to help you choose the right asphalt sealcoating equipment, asphalt products and solutions that will help you get the job done quickly and profitably.

Don't take our word for it: read what our clients have to say about our asphalt products, asphalt equipment and our customer service.