- Help Desk

- Spray Systems

Spray Systems

My system is not agitating.

You get this when the sealer is too thick and the pump cannot create a prime to circulate the sealer. Dilute it properly to achieve 20 to 30% water dilution.

Use a dipstick to check the level of your sealer at the end of the day and the next time you use your system, just in case of water evaporation (if the levels are different, add enough water to regain the previous sealer level).

Another possible reason could involve the system's ball valve. On the output part of the pump, there's a ball valve that allows you to redirect the sealer to the top of the tank or to the spray gun. If that ball valve is constantly or permanently broken to the spray gun, you wouldn't get recirculation.

Hello i bought a ak spray sytem and the filter kit.can you please tell me where i attach the filter kit thanks.

We recommend that you have the filter "pointing" down, that way gravity will help move particulates out of the way of the main flow.

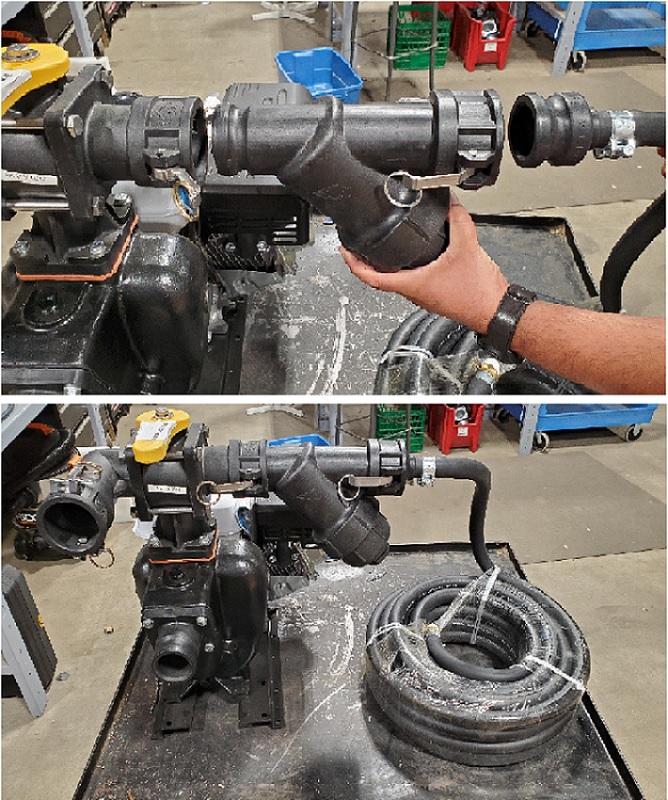

The filter connects to the output port of the pump, and then your spray hose connects to the filter kit. Steps on how to assemble the Filter Kit:

- Insert filter into main valve, close camlocks, insert cotter pins

- Insert spray hose into other end of filter, close camlocks, insert cotter pins.

How much pressure will lose if a 75ft hose is used instead of 50ft hose?

Will this system spray sealer with sand?

How do I remove or clean off the sealer stain when it dried out?

How do I install the seal replacement kit on my spray system?

For all RynoWorx Spray Systems manufactured since 2017, use the Aluminum Pump Mechanical Seal/Ceramic for the Launtop Engine/Aluminum Pump and the Viton/Tungsten Seal Assembly 3/4" shaft for the Launtop Engine/Cast Iron Pump and the Honda Engine/Cast Iron Pump.

Watch the instructional videos on how to install the Aluminum Pump Mechanical Seal/Ceramic and the Viton/Tungsten Seal Assembly 3/4" shaft.

What is the best size trailer to use with this spray system?

How do you agitate the sealer inside a tote?

There are 4 ways to mix sealer inside a tote prior to application or transfer to your sealcoat tank:

1. Use one of our portable spray systems to connect to the tote's suction port and the tote's return feed. Recirculate the sealer for 4 to 5 minutes.

2. Use a compressor with a long 6’ lance to stick down in the top port of the tote. Push the air from the compressor throughout the bottom of the tote to bubble and agitate the material for about 15 minutes.

3. Do both of the above together for optimal sealer agitation results.

4. Use an IBC electrical tote mixer that is mounted on top of the tote. The mixer has a long shaft with a mixer head on it that spins inside the tote to agitate. These electric mixers are quite costly so option 3 above is generally the most commonly used.

- Page

- Page 1

- You're currently reading page 2