AK275 Tote Sealcoating Spray System

Add AK Make it a Biz Success Pack - Free With Purchase

Make up to $9,625 per tote of sealer — just add a tote of sealer and you can spray up to 27,500 square feet!

- Quick-connect hookup to a 275-gal tote

- 150 lb unit loads in a pickup bed or trailer

- Self-priming pump for easier startup and use

Availability: In stock

Have questions? We’re here to help!

Speak to an Asphalt Expert!

Unleash Your Sealcoating Business's Full Potential with the AK275 Tote Sealcoating Spray System

- Acrylic or water-based sealer spray system

- Self-priming pump makes it an easy-to-use spray system

- Connects directly to a 275 gallon tote (not included) with our innovative quick-connect fittings

- Includes 50 feet of sealer hose, three sealcoat spray tips, and a 6 foot spray wand

- Use for large jobs where a drum of sealer is not enough.

If you need to sealcoat larger areas and the AK55 Sealer Sprayer For Drums just won't give you enough square footage, the AK275 Tote Sealcoating Spray System is the next step up. It allows you to hook directly up to a 275 Gallon tote. The system is great for new contractors, property managers, as well as do-it-yourself parking lot owners. Though similar to the Drum Kit unit, this unit is my recommendation for contractors or property owners that have larger jobs where a single drum may not be enough sealer.

As a property owner this unit will cut your asphalt maintenance costs down substantially by allowing you to seal your own lot. If you're a contractor just getting started with asphalt sealcoating, this unit will more than triple your investment in a single tote. If you complete 27,500 sq ft at 35 cents per square foot you can generate $9,625 in gross revenue from just one full tote of sealer. It takes less than 10 minutes for the built in re-circulation system to mix the sealer and you’re ready to start sealing.

Pricing and warranty notes

- Make $0.35 per square foot

- Sprays acrylic and water-based sealer only

- Sealcoating equipment with 1-year warranty

What Our Customers Say:

"We could not be happier with our business relationship with Asphalt Kingdom. The products are top quality and the customer service is excellent. Thanks guys."

Randy Morris

Equipment Manager, Barnes Farming Corporation

"It has been a pleasure to work with the team at Asphalt Kingdom. Truly committed to raising the bar when it comes to customer service."

Paul Jefferson

CEO, Super Nova Holding Group

Is it easy to use the AK275 Sealcoating Spray System?

Let's face it: there's nothing worse than getting a new machine and not being able to use it! But RynoWorx designed this machine to be easy to use right from the first time. You simply need to attach it to a tote of sealer with its quick-connect fitting. Move the valve to 'circulation' mode, and let it run 10 minutes to thoroughly mix the sealer. You don't want to let it run longer: in my experience that can result in air bubbles forming which will make for an uneven spray job. Once you're done agitating, move the valve to 'spray' mode, and go!

Weight: At 150 lbs, this machine is light enough for you to put in the bed of a pick up truck or on a trailer.

Coverage: A 275 gallon tank of sealer will cover up to 27,500 sq ft. Tank sold separately.

Sealer Types: Please note, this system uses acrylic or water-based sealer only. Do not attempt to spray oil-based or petroleum seal coat as it will ruin the machine and void your warranty.

Note: Do not use sand with this spray system.

I go into more detail about the specifications of this affordable, portable sealcoating spray system in the video below, I filmed during a visit at RynoWorx's headquarters. Check it out and let me know if you have any questions - my team and I are always happy to help!

Please note: The AK275 Tote Sealcoating Spray Systems are designed to work with our sealer totes and proprietary camlock connectors. If you want to use your own tote, the tote will need to have a 2" male camlock (ideally with a 90 degree bend) and a threaded adapter to be compatible with the tote sprayer. Threaded adapters vary, so we recommend checking your local plumbing supply stores to find the best fit.

Have questions? We’re here to help!

Speak to an Asphalt Expert!

| Weight | 150 lbs |

| Dimensions | 29" x 29" x 22" |

| Engine Options | Launtop LT210 7.0HP Four-Stroke Engine with Low Oil Shutdown, Recoil Start or Honda GX160 5.5HP Four-Stroke Engine with Low Oil Shutdown, Recoil Start |

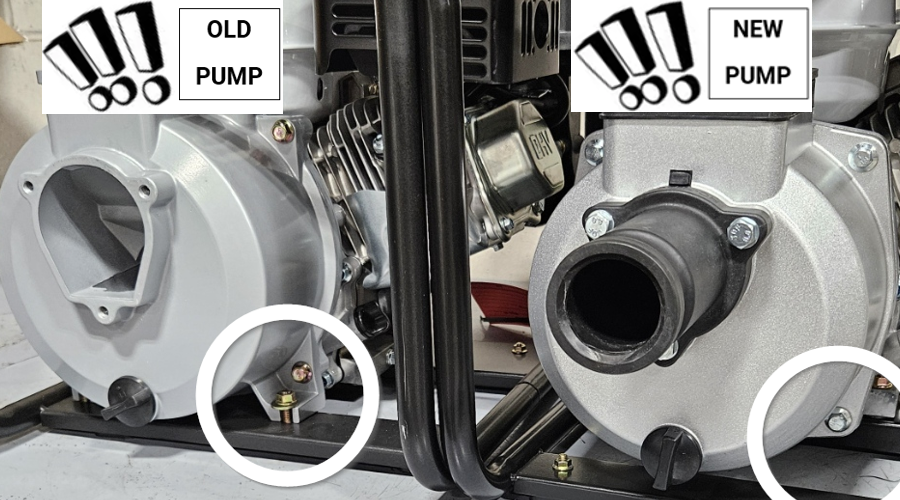

| Pump | 2" Cast Iron Centrifugal Pump Severe Duty, Viton/Tungsten Mechanical Seal Cast Iron Impeller Stainless Steel Wear Plate |

| Tank Fitting | Plug & Play with all 275 Gallon IBC Totes (sold separately) which Contain a 2” Male CamLock Drain Valve and 2” NPT Threaded Opening on the Cap |

| Included Accessories | 6’ Ball Valve Gun w Hose Swivel 2GPM, 3GPM, 4GPM Quick-Connect Spray Tips (1/Each) 50’ x ¾” – 275psi Rated Sealcoating Hose Quick-Connect 3-Way Valve Quick-Connect Cam-Lever Fittings |

| Performance | Agitation occurs through pump recirculation @ 165GPM Spraying Pressure 45psi at Tip |

| Sealer Compatibility | Refined coal tar emulsion without additives Asphalt emulsion without additives |

5

5 stars

100% (5)

4 stars

0% (0)

3 stars

0% (0)

2 stars

0% (0)

1 star

0% (0)

Share your thoughts with other customers

Top customer reviews

- This company and its staff are simply the best.We are setting up to do maintenance on the parking lots of our Kingdom Halls in Virginia. Asphalt Kingdom has been so helpful, from the products and equipment we needed to the video library linked to their site. They have been quick to answer our technical questions as well. Once I sent an email to check on an order of sealer to see what tracking I could get, I got a call back in less than 5 minutes. This company and its staff are simply the best.

- Keep sharing and showing us the ropes cause it’s helped me tremendously!Hey Judd obviously I don’t know you personally but wanted to share with you! Back early July I was working for a Asphalt paving company making 20$ a hour I was pretty miserable in life because I knew I wanted more … I been working on and off with this company since 2015 so I have sealcoating experience. I was searching for a sealcoat tank and set ups online and found Asphalt kingdom ???? I ended buying a new pick up truck sealcoat tank and motor/cast iron pump from you guys … Macky Lorca one ofRead more your specialists has sat on the phone with me for at least a couple hours now altogether teaching me all about my new system she is amazing and lately work has been booming and kicking ass! My company J&L Sealcoating LLC has had a great season and I started super late practically August! I got my LLC and EIN # …Next year is gonna be a great year! Keep sharing and showing us the ropes cause it’s helped me tremendously! Check out my website when you get the chance! Jandlsealcoating.com and J&L Sealcoating LLC on Facebook and tell me what you think!???????? Appreciate you guys!

-Josh Laprade - Great productI am very impressed with this product. I started Atlas Sealcoating a few months ago and it’s going great! I needed a sprayer system as we moved into larger commercial lots. The AK275 is great for smaller businesses on a budget. I’ve done some great lots with this sprayer! I would definitely recommend getting the filter kit. It’s easy to install and makes your life so much better by avoiding clogs.

- Top quality equipmentMy experience doing business with asphalt kingdom was second to none Glenn Teano is my salesman. I was approved for $20,000 in financing and I put a whole list together of all types of things that I needed. But I wanted to take it slow put a little bit and now a week later a little bit more. He was great with that not pushy not trying to rack up my credit line just to make a sale. He took his time explain things to me when I had questions he had all the answers. I just can’t say enough about thiRead mores company after two weeks I’ve received half of my order and it’s all Bill very very well top quality equipment thank you Asphalt kingdom.

- We could not be happier!We could not be happier with our business relationship with Asphalt Kingdom. The products are top quality and the customer service is excellent. Thanks guys.

- Super ServiceJe parle français et mon contact a cette endroit est Jennifer elle donne un super service merci beaucoup

Start your Asphalt Maintenance Business just like Judd did!

Our founder, Judd Burdon, started in the asphalt business by sealcoating driveways and parking lots. It's a great niche service that helps prolong the lifespan of the pavement, and makes it look great. Click to add the Make it A Business resources to your spray system order, absolutely free:

- Role-Practice Video: Judd Burdon walks you through how to pitch sealcoating to prospects, including the questions you should ask them and the most likely questions they will have for you. Learn from the master!

- Phone Script: Swipe this powerful phone script and convert customers faster when you're prospecting. Use it yourself or hire someone to generate jobs while you're out working.

- Social Media Templates: Just add your logos to these great-looking graphics, post on your social media, and spread the word about your sealcoating business. You'll love the action you see from these lead generating images!

- Sealcoating Proposal Template: Use this proven template to fill in, print off and present to prospects. When your business looks professional, you can charge more for your services.

- Access to the AK Round Table: Want to join a group of like-minded people on a journey to build their own asphalt maintenance empire? Get access to our weekly Zoom meeting and get answers to your most pressing questions.

Starting an asphalt maintenance business can be scary if you don't have the resources you need to succeed. Let us do the heavy lifting for you. Make It A Biz!