AK55 Sealer Sprayer for Drums

Add AK Make it a Biz Success Pack - Free With Purchase

The pavement sealing machine mixes and sprays asphalt sealer from drums and can cover up to 6,500 square feet.

- Everything you need to jumpstart your business

- Make your investment back in 1 job!

- 1-year warranty

Have questions? We’re here to help!

Your Sealcoating Business Is On The Right Track with the AK55 Asphalt Sealer Sprayer for Drums

If you've ever wanted to start your own asphalt sealcoating business without a large investment or you're a property owner looking to maintain your parking lot or driveway without breaking the bank, then look no further. When I got started in this business it was with a five gallon pail and a squeegee — talk about time-consuming! I was pretty fast with the squeegee but it was nowhere near as fast as when I bought my first spray system. Spraying saves time, uses less product and creates a better finish.

The Drum Sprayer Kit is the most affordable way to get started sealing today. This machine allows you to circulate and apply sealer directly from any 205-liter (55-gallon) drum. It delivers professional results without a large footprint or price tag. The portability and lightweight design allow you to transport it with a small trailer or pick-up truck. It takes less than 5 minutes for the built-in re-circulation system to mix the sealer and you're ready to start sealing.

- Mix and spray sealer from drums.

- With up to 6,500 square feet coverage.

- Compatible with water-based sealers.

Coverage: When sprayed efficiently, a 205-liter (55-gallon) drum should be able to cover approximately 6,500 square feet (that's 10 four-car driveways) of asphalt. That means if you're charging 21 cents per square foot, the AK55 Sealer Sprayer for Drums can pay for itself with less than one full drum of sealer.

Sealer Types: Please note these systems are only designed to work with water-based or acrylic asphalt seal coat. They cannot spray petroleum or oil-based sealer.

What Contractors Are Saying About the AK55

“From buckets to next-level sprayer!

Great system to learn to operate. After the first barrel we were cookin'. Best to have a 2-man crew—harder to operate alone starting out! Good equipment for getting your business off the ground.

Thank you!”

Kevin Mason

By His Stripes LLC

“The AK55 Sealer Sprayer for Drums works great as advertised. I never have problems with it.”

Jacob Theriault

NJT Paving

YOU ASK, WE ANSWER

| Questions | Answers |

|---|---|

| Is special training required to use this equipment or can it be operated effectively without professional help? | No special training required: if you can use a pressure washer, you can use the AK55 Asphalt Sealer Sprayer for drums. It comes with a user-friendly operation manual to ensure ease of use, even for beginners. |

| How often does this machine require maintenance? Are service parts easily accessible and how reliable is it over time? | Designed with high-quality parts for minimal maintenance and includes a detailed maintenance schedule to help keep the machine in peak condition. |

| Isn't it cheaper to use a squeegee than a 55-gallon drum sprayer? | Investing in the AK55 reduces labor costs and increases job efficiency, offering a quick return on investment. You'll get a more even finish and you won't have to figure out what to do with dozens of empty 5-gallon pails. |

Have questions? We’re here to help!

| Shipping Weight | 108 |

| Shipping Length | 36 |

| Shipping Width | 21 |

| Shipping Height | 24 |

| Engine Options | Launtop LT210 7.0HP Four-Stroke Engine with Low Oil Shutdown, Recoil Start or Honda GX160 5.5HP Four-Stroke Engine with Low Oil Shutdown, Recoil Start |

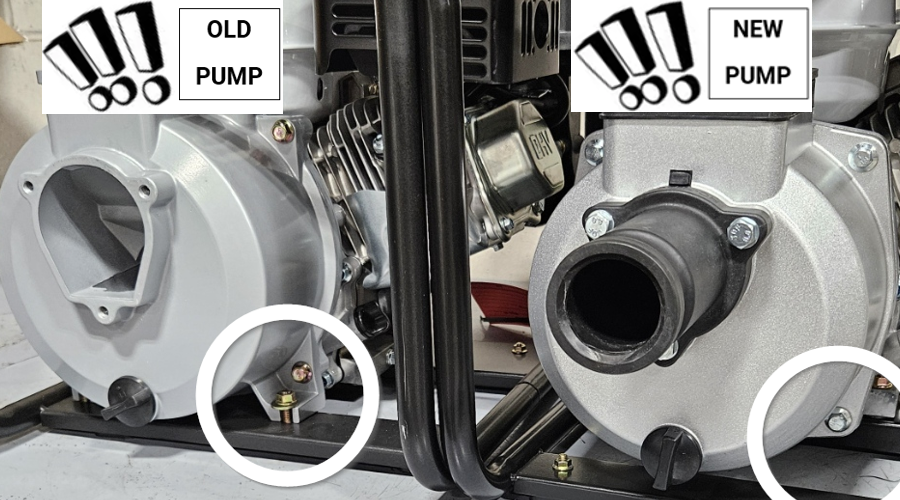

| Pump Specs | Standard:

2” Aluminum Centrifugal Pump Standard Duty, EPDM Mechanical Seal Cast Iron Impeller Or optional upgrade 2" Cast Iron Centrifugal Pump Severe Duty, Viton/Tungsten Mechanical Seal Cast Iron Impeller Stainless Steel Wear Plate |

| Tank | None Included Includes Quick Connect Sprayer Kit to spray sealer from 55 Gallon Drums (Drums sold separately) |

| Included Accessories | 50’ x ¾” – 275psi Rated Sealcoating Hose 6’ Ball Valve Gun w Hose Swivel 2GPM, 3GPM, 4GPM Quick-Connect Spray Tips (1/Each) Quick-Connect 3-Way Valve |

| Performance | Agitation through pump recirculation @ 165 GPM Sprayer Pressure: 45 psi at tip |

| Sealer Compatibility | Refined coal tar emulsion without additives Asphalt emulsion without additives |

4.7

5 stars

71% (5)

4 stars

14% (1)

3 stars

14% (1)

2 stars

0% (0)

1 star

0% (0)

Share your thoughts with other customers

Top customer reviews

- Great starter machineGreat machine if your just starting a business! Recommend

- I'm extremely happy with Asphalt KingdomI'm extremely happy with Asphalt Kingdom and the new relationship I have with this company. The products are amazing, the pricing is right on point and shipping is fast and free. The customer service goes above and beyond helping out people like me, just starting out in the business, with any and all questions I have, every time I call. What more can you ask for?

- Property management must haveThe ak55 is a great tool, affordable, easy to use, we saved thousands using our own maintenance team rather than contracting out with this machine. Outstanding service as well! Thank you

- Crackfilling and Sealcoating are really simpleEverything is fine. It took me a little bit of a learning curve. The videos on the website are really helpful for a starter like me. I realize that Crackfilling and Sealcoating are really simple. You just need to get the right equipment for you. I'm happy with my purchase looking forward to doing more business with you in the future

- Never had problems with my AK55The AK55 Sealer Sprayer For Drums works great as advertise. I never had problems with it.

- From buckets to next level Sprayer!Great system to learn to operate. After the first barrel we were cookin. Best to have 2 man crew, harder to operate alone starting out! Good equipment getting your business off the ground.

- AK55 Sealer Sprayer for DrumsThe pump works great, after getting the 3 way valve to work. Started by stirring the barrel. Drill attached agitator for about 5 min. then prime and start the pump on recirc. recirc for about 5 min then switched to spray mode and it plugs up. clean strainer. And repeat 3 or 4 times. No biggie other then the 3 way valve fills with the sand that is in sealant and becomes almost impossible to turn until the plastic handle cracks. Then we pull the valve about clean and grease the ball and re assemblRead moree and now we just don't use the recirc feature. Other then a cheap valve this set up works great!

Start your Asphalt Maintenance Business just like Judd did!

Our founder, Judd Burdon, started in the asphalt business by sealcoating driveways and parking lots. It's a great niche service that helps prolong the lifespan of the pavement, and makes it look great. Click to add the Make it A Business resources to your spray system order, absolutely free:

- Role-Practice Video: Judd Burdon walks you through how to pitch sealcoating to prospects, including the questions you should ask them and the most likely questions they will have for you. Learn from the master!

- Phone Script: Swipe this powerful phone script and convert customers faster when you're prospecting. Use it yourself or hire someone to generate jobs while you're out working.

- Social Media Templates: Just add your logos to these great-looking graphics, post on your social media, and spread the word about your sealcoating business. You'll love the action you see from these lead generating images!

- Sealcoating Proposal Template: Use this proven template to fill in, print off and present to prospects. When your business looks professional, you can charge more for your services.

- Access to the AK Round Table: Want to join a group of like-minded people on a journey to build their own asphalt maintenance empire? Get access to our weekly Zoom meeting and get answers to your most pressing questions.

Starting an asphalt maintenance business can be scary if you don't have the resources you need to succeed. Let us do the heavy lifting for you. Make It A Biz!