AK130 Pro Sealcoating Spray System

Add AK Make it a Biz Success Pack - Free With Purchase

The AK130 Pro Sealcoating Spray System with filter kit, hose reel, transfer kit and maintenance kit included. Spray more and earn more with this high-capacity sealcoat sprayer.

- Heavy-duty 5.5 HP engine

- High-capacity steel tank

- Includes essential add-ons

Availability: In stock

Have questions? We’re here to help!

Reliable Performance with the AK130 Pro Sealcoating Spray System

The Ferrari of our spray systems, loaded with all of the add-ons:

- AK130 spray system

- Hose reel

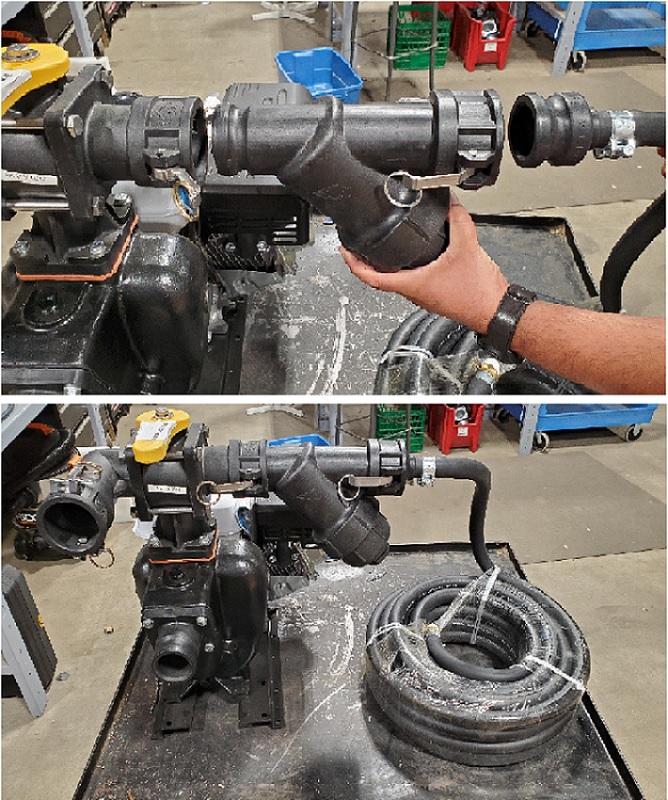

- Filter kit with removable filter

- Transfer kit for asphalt sealcoat

- And a Spray Systems Essentials Kit (includes spare pump seal, pack of 3 spare tips, 3 replacement mesh filters and one ¾” ball valve)

The AK130 Pro comes with efficiency-boosting add-ons and additional parts for maintenance so you won't have to wait for replacement parts for your sealcoating machine when they wear out.

What Other Customers Say:

“The machine works great and helps me a lot with my job.“

Jeffrey Evans

Founder & President at Chattahoochee Valley Sealcoating, LLC

Maximizing Your Efficiency

Powered by a dependable 5.5 HP Honda engine and a cast-iron pump, this 130-gallon spray system provides up to 13,000 square feet of coverage with each full tank. This asphalt sealer sprayer is your reliable partner in sealing large parking lots and multiple driveways.

The included hose reel winds up 50 feet of 3/4" hose, and can be mounted to a truck or trailer. A filter kit provides protection against debris going through your spray wand and hitting your spray tip. The transfer kit is a necessary tool for moving sealer into your tank from drums or totes of sealer.

Note: Do not use sand with this spray system.

Have questions? We’re here to help!

| Engine | Honda GX160 5.5HP Four-Stroke Engine with Low Oil Shutdown, Recoil Start |

|---|---|

| Pump |

|

| Tank |

|

| Features |

|

| Performance |

|

| Dimensions | 51.5" x 33.75" x 40" |

| Weight* (empty) | 375 lbs |

| Weight* (full) | 1875 lbs |

*Weights do not include the weight of hose reel, filter kit, and maintenance kit

4.8

5 stars

40% (2)

4 stars

60% (3)

3 stars

0% (0)

2 stars

0% (0)

1 star

0% (0)

Share your thoughts with other customers

Top customer reviews

- Helps me a lotThe machine works great and helps me a lot with my job

- AK130 ProVery nice machine for residential work

- Changed my lifeI bought this machine in the beginning of the spring I must say I’m very impressed with this machine sprays awesome got a lot of pressure and also looks pretty bad ass but I just want to say that this machine changed my life now I can maximize my profits and be more efficient thank you to Judd Burdon

- Awesome piece of equipment so far.Everything working great so far

- Awesome piece of equipment so far.Fast shipping

Start your Asphalt Maintenance Business just like Judd did!

Our founder, Judd Burdon, started in the asphalt business by sealcoating driveways and parking lots. It's a great niche service that helps prolong the lifespan of the pavement, and makes it look great. Click to add the Make it A Business resources to your spray system order, absolutely free:

- Role-Practice Video: Judd Burdon walks you through how to pitch sealcoating to prospects, including the questions you should ask them and the most likely questions they will have for you. Learn from the master!

- Phone Script: Swipe this powerful phone script and convert customers faster when you're prospecting. Use it yourself or hire someone to generate jobs while you're out working.

- Social Media Templates: Just add your logos to these great-looking graphics, post on your social media, and spread the word about your sealcoating business. You'll love the action you see from these lead generating images!

- Sealcoating Proposal Template: Use this proven template to fill in, print off and present to prospects. When your business looks professional, you can charge more for your services.

- Access to the AK Round Table: Want to join a group of like-minded people on a journey to build their own asphalt maintenance empire? Get access to our weekly Zoom meeting and get answers to your most pressing questions.

Starting an asphalt maintenance business can be scary if you don't have the resources you need to succeed. Let us do the heavy lifting for you. Make It A Biz!