AK130 Sealcoat Sprayer for Residential Sealcoating

Add AK Make it a Biz Success Pack - Free With Purchase

Mounts on 1 ton truck or larger. 130 gal tank covers 13,000 sq ft of surface.

- High-capacity solid steel tank

- Rugged and dependable engine

- Sprays water-based or acrylic sealer

Availability: In stock

Have questions? We’re here to help!

Speak to an Asphalt Expert!

Specialize in Residential Sealcoating? Choose the AK130 Residential Sealcoat Sprayer!

The AK130 Sealcoat Sprayer is the ideal setup for someone looking to start a driveway sealing company or an existing contractor looking to add steady income streams to their existing business. This sealcoating machine will easily fit in the back of a light pickup truck or small trailer.

- Ideal for small driveway sealing contractor

- 130-gallon professional steel tank

- Carries up to 130 gallons to cover 13,000 square feet

- Will fit comfortably in a half-ton pickup truck or trailer

- A spray gun and three tips are included

At .25¢ per square foot, you can generate $3,250 in revenue. In as little as 1.5 tanks, you can pay for this unit and still have money in your pocket.

What Other Customers Say:

“The people at Asphalt Kingdom are amazing, definitely a 10 out of 10 experience getting to know & do business with them.“

John Vanzyl

Owner, Xtreme Sealcoating

Tank: We’ve designed this residential sealcoating unit with you in mind from top to bottom. This unit features a puncture-proof 11-gauge steel tank that won’t warp with pressure buildup or weather fluctuation like lower-value poly tanks. We’ve manufactured this sealcoating machine with a large double splash manhole opening; this allows for easy cleaning and maintenance of your tank as well as spill prevention during transport. You may also use the manhole for transferring sealer or adding water to meet proper dilution.

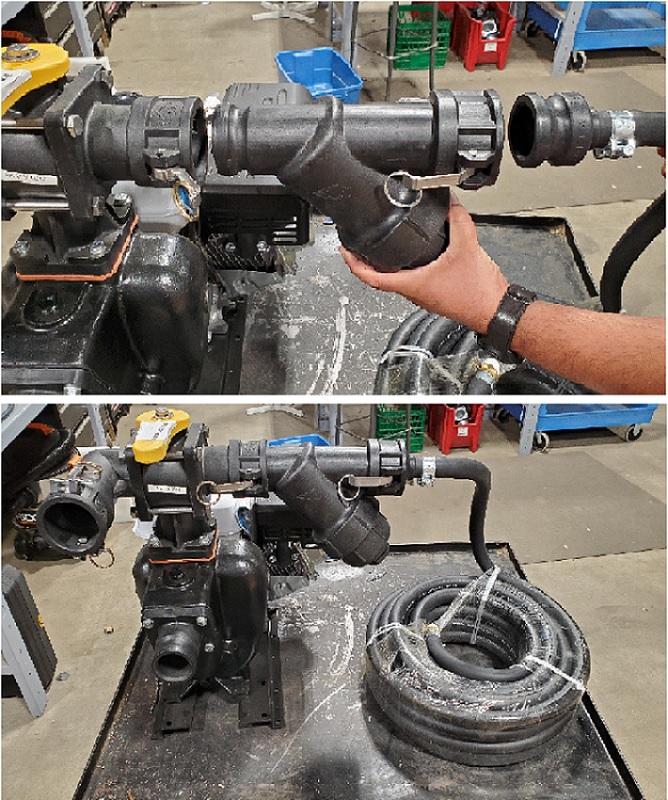

Engine & Pump: This unit comes standard with an engine and pump with professional-grade Viton seals. The included spray gun makes cutting in the edges of the driveway simple and gives you precise control over the amount of sealer that is applied with a streak-free finish.

Coverage: The 492 Litre (130 Gallon) steel tank, when full, can cover close to 13,000 square feet.

Sealer Types: Our systems spray water-based or acrylic sealer only. This sealcoat spray system does not work with petroleum or oil-based sealer, gilsonite, or any asphalt sealcoat with sand in it. If you are purchasing sealer from anywhere other than Asphalt Kingdom, please check with your sealer manufacturer to ensure compatibility. We are unable to guarantee compatibility between our residential sealcoating equipment and any sealer other than our own since we have no way of verifying the manufacturing process, abrasiveness, or viscosity of the material.

How to Know if You Can Seal Over Oil Spots – The Key Test

Before applying sealer on a driveway with oil stains, you need to be sure the surface can actually hold the sealcoat. Oil can prevent bonding, leading to peeling, flaking, or early failure. Here’s a simple on-site method to check:

The Key Test

This quick test helps prevent adhesion problems and ensures your residential sealcoating lasts, especially on driveways with oil contamination.

A popular upgrade for our asphalt sealcoating spray systems is the Fast Sealer Transfer Kit. This kit plugs directly into all Asphalt Kingdom Spray Systems and is required to load sealer from any drum or tote. Spray wand included.

Note: Do not use sand with this spray system.

Frequently Asked Questions

While the exact time frame depends on traffic, climate, and surface preparation, sealcoating typically lasts two to three years. Regular reapplications can lengthen this time frame.

Most charge anywhere between $0.15 and $0.35 per square foot, adjusting rates based on the driveway’s condition and the difficulty of the job. If you charge an average of $0.25 per square foot, that means earning $3,250 for a 13,000-square-foot job!

Yes, using a sprayer like the AK130 Sealcoat Sprayer ensures even, streak-free coverage. Plus, it’s much faster than applying sealcoat material by hand, especially when you have a big job or multiple smaller jobs.

Have questions? We’re here to help!

Speak to an Asphalt Expert!

| Shipping Weight | 437 |

| Shipping Length | 51.50 |

| Shipping Width | 33.75 |

| Shipping Height | 40 |

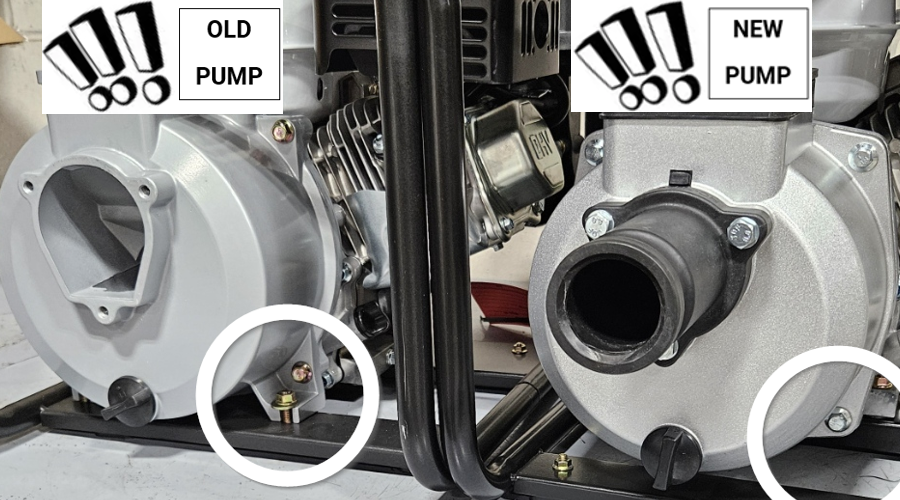

| Pump Type | Cast Iron Centrifugal Pump

|

| Engine | Briggs & Stratton 12S 6.5HP Gas Engine

|

| Tank |

|

| Hose |

|

| Wand |

|

| Capacity | 492 litres / 130 Gallons |

| Weight (Empty/Full) | 397 / 1497 lbs |

| Manuals |  Download the AK130 Manual Download the AK130 Manual  Why do Mechanical Seals Fail? Why do Mechanical Seals Fail?  1 Year Limited Warranty 1 Year Limited Warranty |

5

5 stars

100% (3)

4 stars

0% (0)

3 stars

0% (0)

2 stars

0% (0)

1 star

0% (0)

Share your thoughts with other customers

Top customer reviews

- 10/10 recommend Asphalt KingdomStarting out I bought my sealcoating equipment through Asphalt Kingdom and don’t regret it at all! Gave me the right equipment I needed to be successful and gave me the confidence to start the journey on my own. 10/10 recommend Asphalt Kingdom

- a 10 out of 10!The people at Asphalt Kingdom are amazing definitely a 10 out of 10 experience getting to know & do business with them.

- No issues since thenWhen they first got the machine, it was leaking really bad, but after tightening the screws on the pump, the machine worked really great and had not had any issues since then. - Leona

Start your Asphalt Maintenance Business just like Judd did!

Our founder, Judd Burdon, started in the asphalt business by sealcoating driveways and parking lots. It's a great niche service that helps prolong the lifespan of the pavement, and makes it look great. Click to add the Make it A Business resources to your spray system order, absolutely free:

- Role-Practice Video: Judd Burdon walks you through how to pitch sealcoating to prospects, including the questions you should ask them and the most likely questions they will have for you. Learn from the master!

- Phone Script: Swipe this powerful phone script and convert customers faster when you're prospecting. Use it yourself or hire someone to generate jobs while you're out working.

- Social Media Templates: Just add your logos to these great-looking graphics, post on your social media, and spread the word about your sealcoating business. You'll love the action you see from these lead generating images!

- Sealcoating Proposal Template: Use this proven template to fill in, print off and present to prospects. When your business looks professional, you can charge more for your services.

- Access to the AK Round Table: Want to join a group of like-minded people on a journey to build their own asphalt maintenance empire? Get access to our weekly Zoom meeting and get answers to your most pressing questions.

Starting an asphalt maintenance business can be scary if you don't have the resources you need to succeed. Let us do the heavy lifting for you. Make It A Biz!