AK230 Sealcoat Sprayer

Add AK Make it a Biz Success Pack - Free With Purchase

230 Gallon Spray System for parking lot sealcoating.

- Rugged 12-gauge steel tank

- Can hold up to 230 gallons of asphalt sealcoat

- Beginner-friendly machine

Availability: In stock

Have questions? We’re here to help!

Getting Ready to Scale? Then the AK230 Sealcoat Sprayer is Designed for You

The AK230 gallon spray system is built for the full time driveway sealing contractor. With its full capacity, the 870 Litre (230 Gallon) tank will allow you to carry sealer without interrupting your work schedule with sealer refills.

When this tank is full you should be able to seal close to 23,000 square feet of asphalt. That equals to about 38 driveways averaging 550-600 square feet, or $4,830 in revenue if your jobs are priced properly at 21 cents per square foot. Another benefit of this tank capacity is the ability to complete small parking lot jobs in 1 day without having to refill on product. If you’re confident with taking on parking lot size jobs or want to complete $4,000+ weeks without having to refill then the AK230 is the best way to go.

Tank:

We’ve designed this unit with you in mind from top to bottom. This unit features a puncture proof 11 gauge steel tank that won’t warp with pressure buildup or weather fluctuation like lower value poly tanks. We’ve manufactured this unit with a large double splash manhole opening; this allows for easy cleaning and maintenance of your tank as well as spill prevention during transport. You may also use the manhole for transferring sealer or adding water to meet proper dilution. Manual paddle agitation comes standard so you can keep you sealer properly mixed on the job.

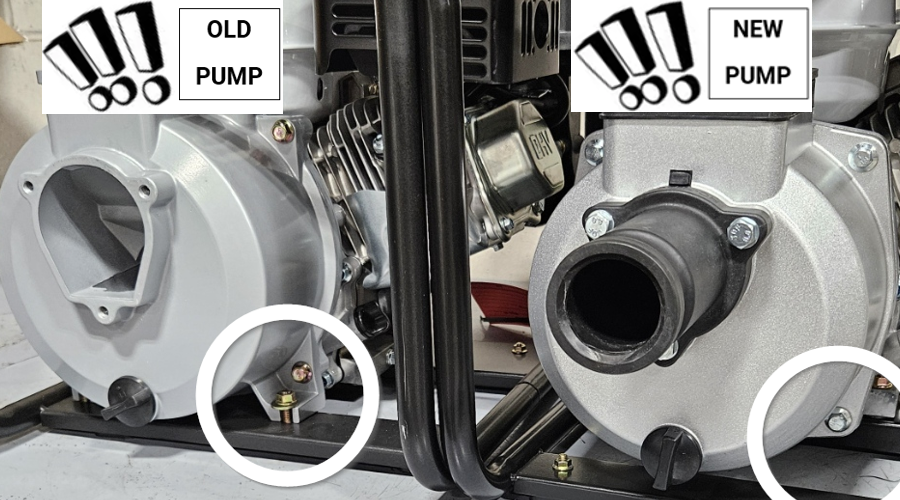

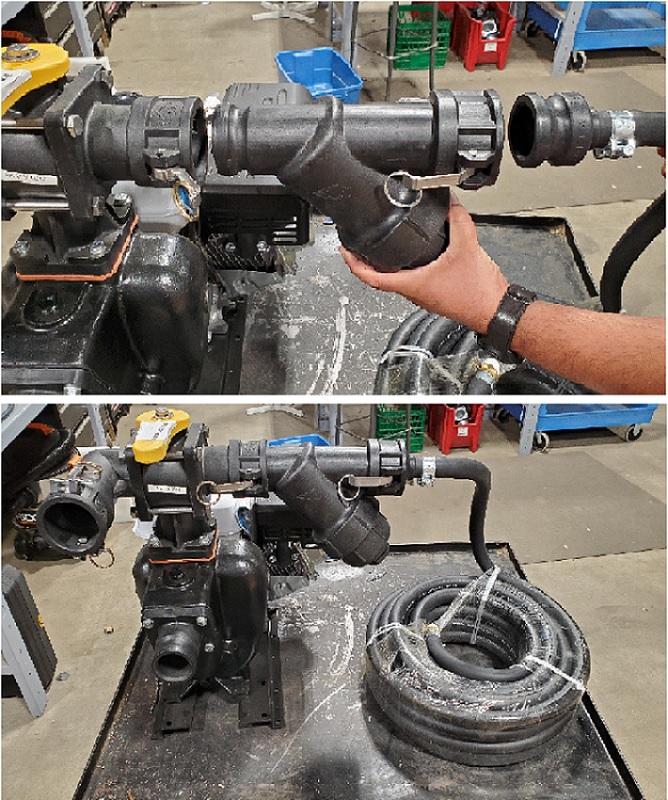

Engine & Pump:

This unit comes standard with a Launtop Engine, and aluminium pump. Upgrade to a 2” centrifugal cast iron pump with Viton seals and cast iron impeller. The trigger gun makes cutting in the edges of the driveway simple and gives you precise control over the amount of sealer that is applied with a streak free finish.

You can also add a filter kit.

Sealer:

Our systems spray water-based or acrylic sealer only. They do not work with petroleum or oil-based sealer. If you are purchasing sealer from anywhere other than Asphalt Kingdom, please check with your sealer manufacturer to ensure compatibility. We are unable to guarantee compatibility with any sealer other than our own.

A popular upgrade for our spray systems is the FAST TRANSFER KIT. This kit plugs directly into all Ryno Spray Systems and is required to load sealer from any drum or tote.

Note: Do not use sand with this spray system.

Have questions? We’re here to help!

| Launtop Engine | Launtop LT210 7.0HP Four-Stroke Engine with Low Oil Shutdown, Recoil Start |

| Honda Engine | Honda GX160 5.5HP Four-Stroke Engine with Low Oil Shutdown, Recoil Start |

| Aluminum Pump |

|

| Cast Iron Pump |

|

| Tank |

|

| Standard Features |

|

| Pro Optional Upgrades |

|

| Performance |

|

| Dimensions | 65.5" L x37.75" W x 42.5" H |

| Weight (empty) | 400 lbs. (aluminum pump) 425 lbs. (cast iron pump) |

| Weight (full) | 2930 lbs. (aluminum pump) 2955 lbs. (cast iron pump) |

| Shop for Replacement Parts: |

5

5 stars

100% (4)

4 stars

0% (0)

3 stars

0% (0)

2 stars

0% (0)

1 star

0% (0)

Share your thoughts with other customers

Top customer reviews

- ExcitedExcited to receive my new AK230 sealcoat sprayer and RY10 PRO asphalt crack fill machine from Asphalt Kingdom. Can’t wait to mount this one in the truck!

- Happy with my purchaseSpray machine was delivered in 5 days. I just finished testing it with water and it works great. Looking forward to my first day spraying on a parking lot tomorrow.

- Top Shelf!I started Wyoming Asphalt Repair with Asphalt Kingdom equipment and material. I am very impressed with the how great the equipment runs and how great the material works. Their customer service and sales team is top shelf!!

- Very PleasedI have been sealing driveways for the past 16 years been using black top sealer

this year I bought a new system an Ak 230 sprayer at asphalt kingdom and purchase my super seal tar Emulsion Driveway sealer. I have used it all summer and my customers are very pleased with the final result. As I was spraying driveways, many people from other areas were very interested in my service and the results from using this product. All in all, I am very pleased with the product and plan on continuing to usRead moree it for many years to come.

Start your Asphalt Maintenance Business just like Judd did!

Our founder, Judd Burdon, started in the asphalt business by sealcoating driveways and parking lots. It's a great niche service that helps prolong the lifespan of the pavement, and makes it look great. Click to add the Make it A Business resources to your spray system order, absolutely free:

- Role-Practice Video: Judd Burdon walks you through how to pitch sealcoating to prospects, including the questions you should ask them and the most likely questions they will have for you. Learn from the master!

- Phone Script: Swipe this powerful phone script and convert customers faster when you're prospecting. Use it yourself or hire someone to generate jobs while you're out working.

- Social Media Templates: Just add your logos to these great-looking graphics, post on your social media, and spread the word about your sealcoating business. You'll love the action you see from these lead generating images!

- Sealcoating Proposal Template: Use this proven template to fill in, print off and present to prospects. When your business looks professional, you can charge more for your services.

- Access to the AK Round Table: Want to join a group of like-minded people on a journey to build their own asphalt maintenance empire? Get access to our weekly Zoom meeting and get answers to your most pressing questions.

Starting an asphalt maintenance business can be scary if you don't have the resources you need to succeed. Let us do the heavy lifting for you. Make It A Biz!